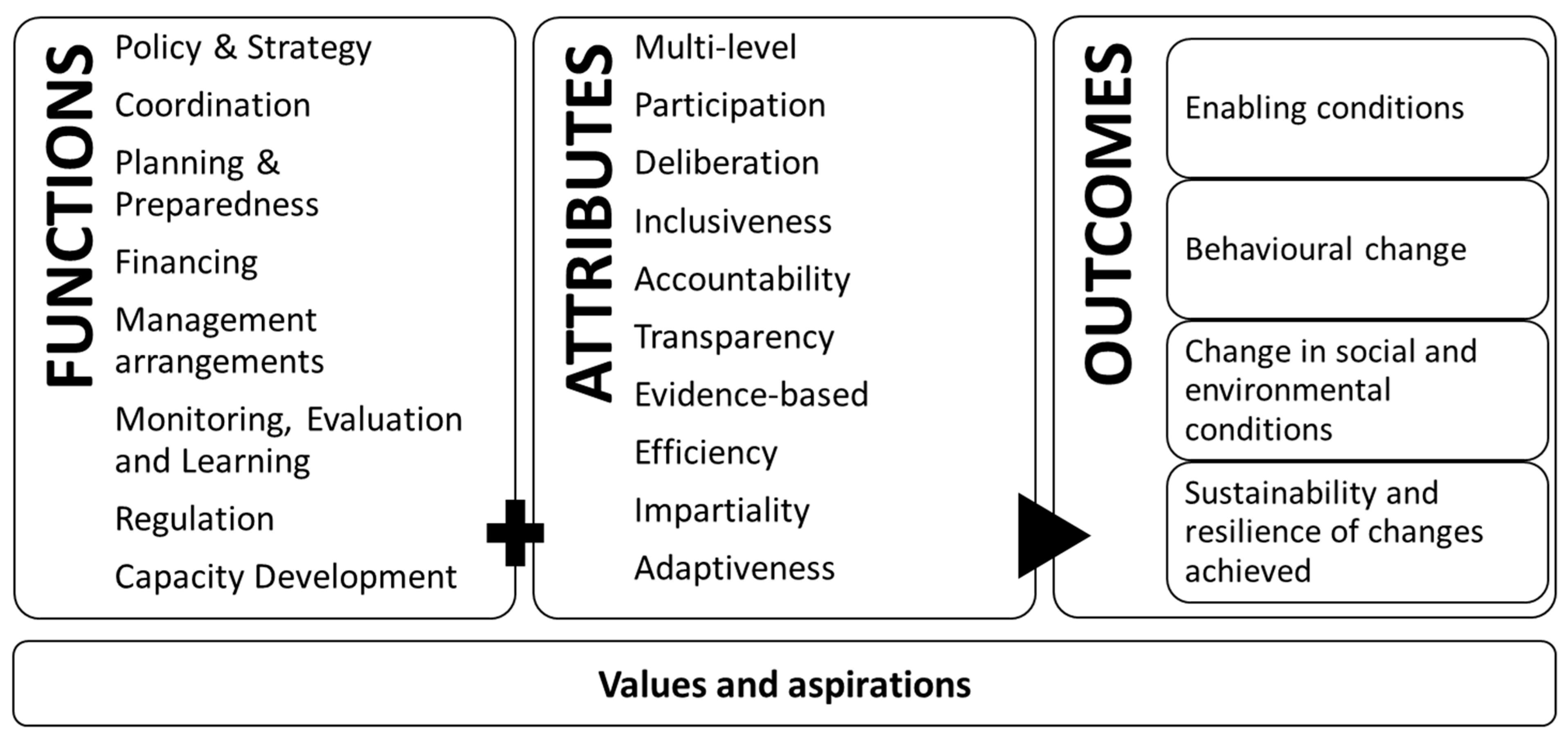

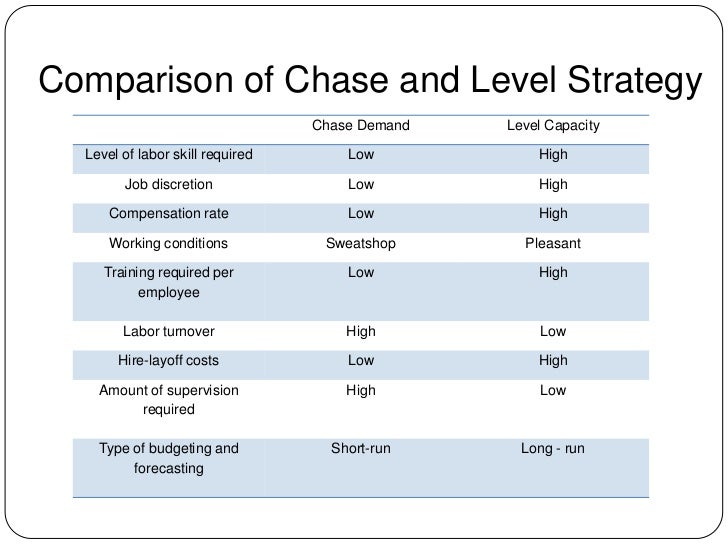

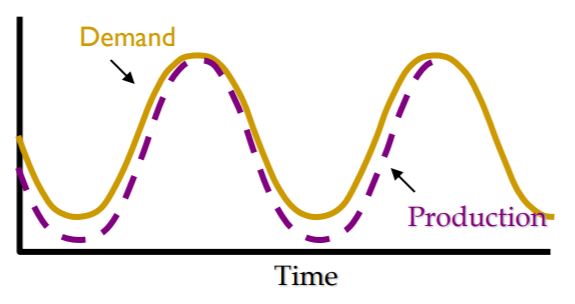

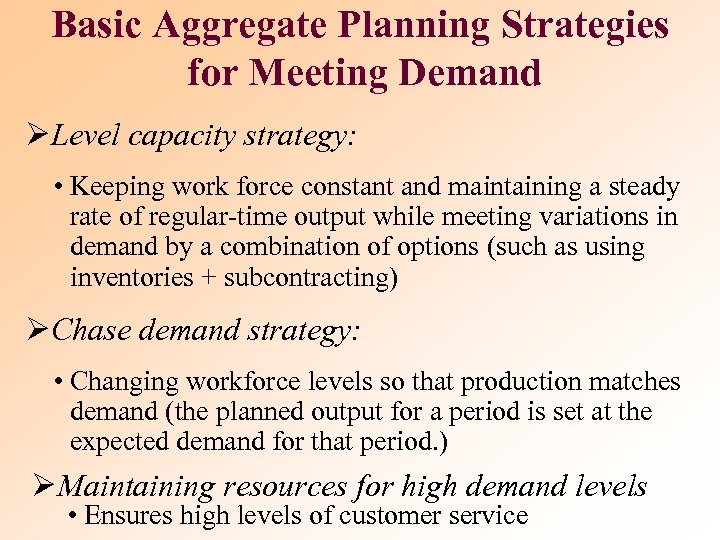

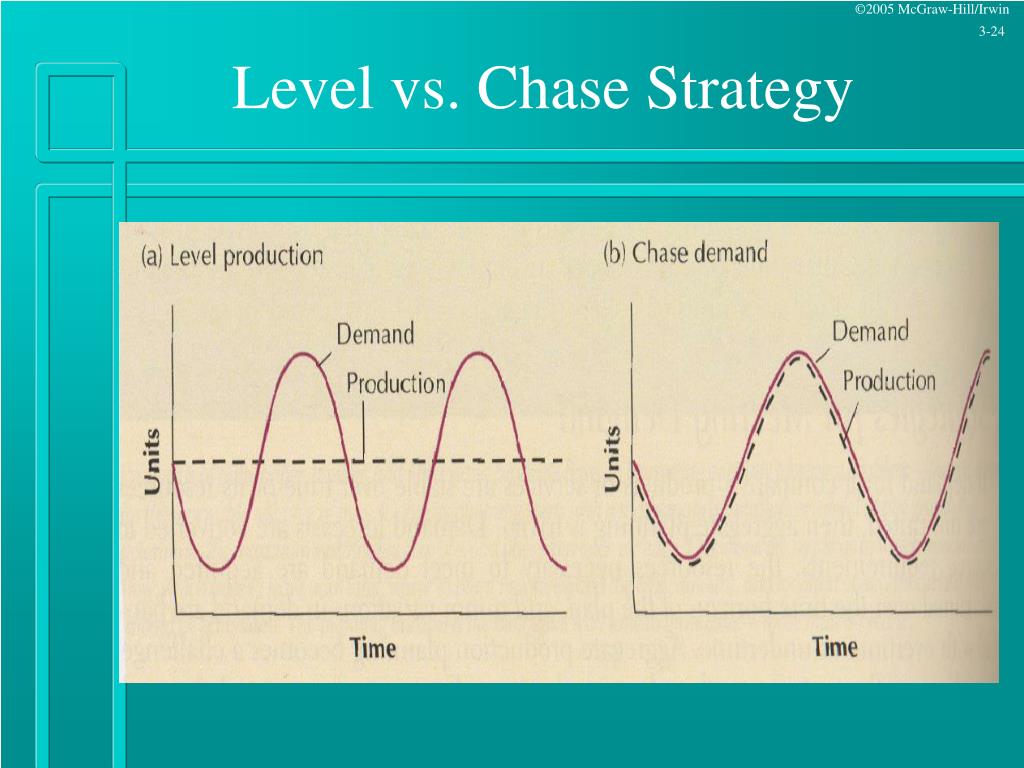

Diversification can occur either at the businessunit level or at the corporate level of economies of scale, economies of scope, new locations, new technology, or some other form of increased competitive capacity Mergers and Acquisitions Mergers and acquisitions (M&A) are aspects of corporate strategy, corporate finance, and managementCapacity planning is a strategic process whereby a company determines what level of capacity it will need to satisfy the level of demand for its products or services over a period of timeIn this rundown of the juggling feat service managers perform, the author discusses the two basic strategies—"chase demand" and "level capacity"—available to most service companies

How To Initiate A Capacity Planning And Management Process For A Rapid Dep Loyment Unit Of A Security Services Company Pdf Free Download

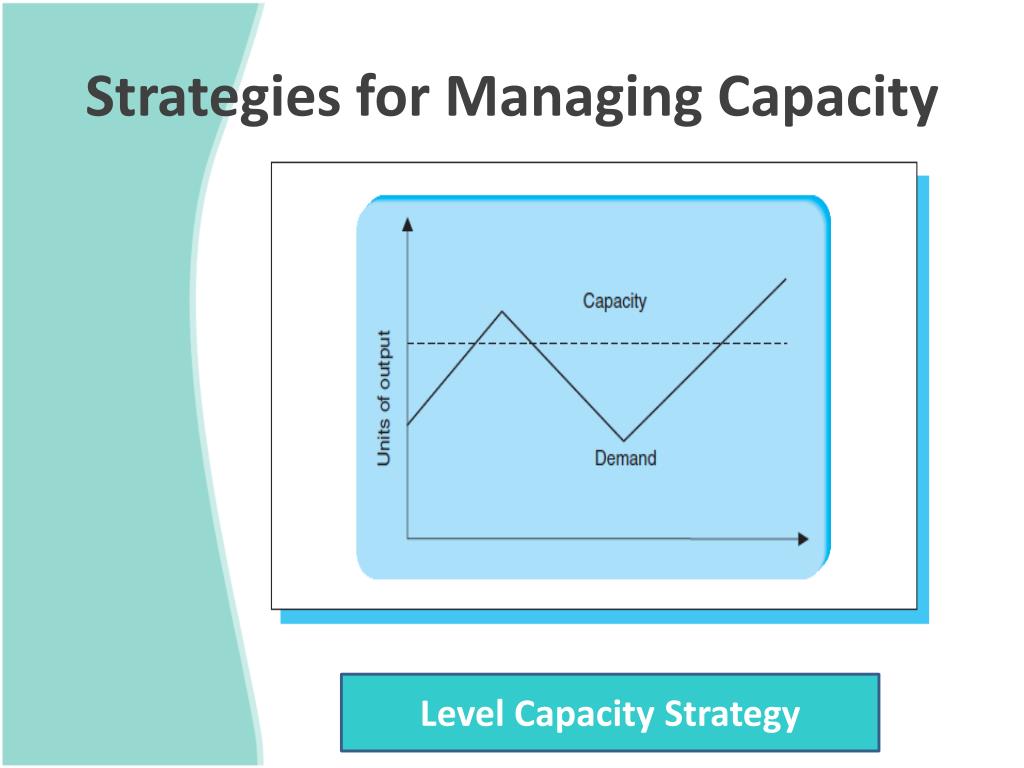

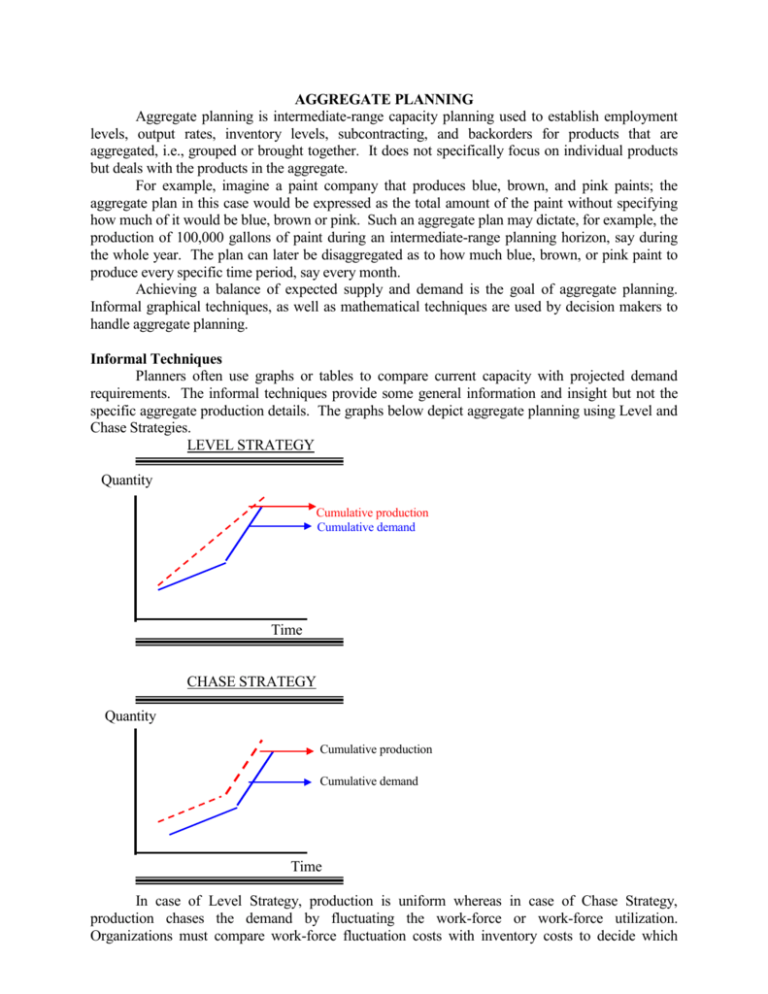

Level capacity strategy

Level capacity strategy-Airline capacity strategies number 2 and 1 are the most used strategies across all regions (524% and 32% respectively) The second str ategy 'VeryLow Capacity' is a dominan tThis A level Business revision tutorial investigates the concept of capacity utilisation in a business and the strategies managers may use if capacity utilis

M Dc Operations Strategy

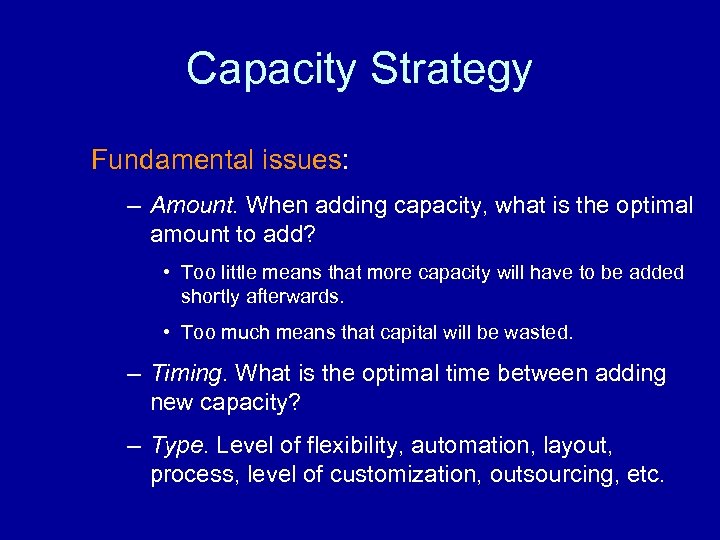

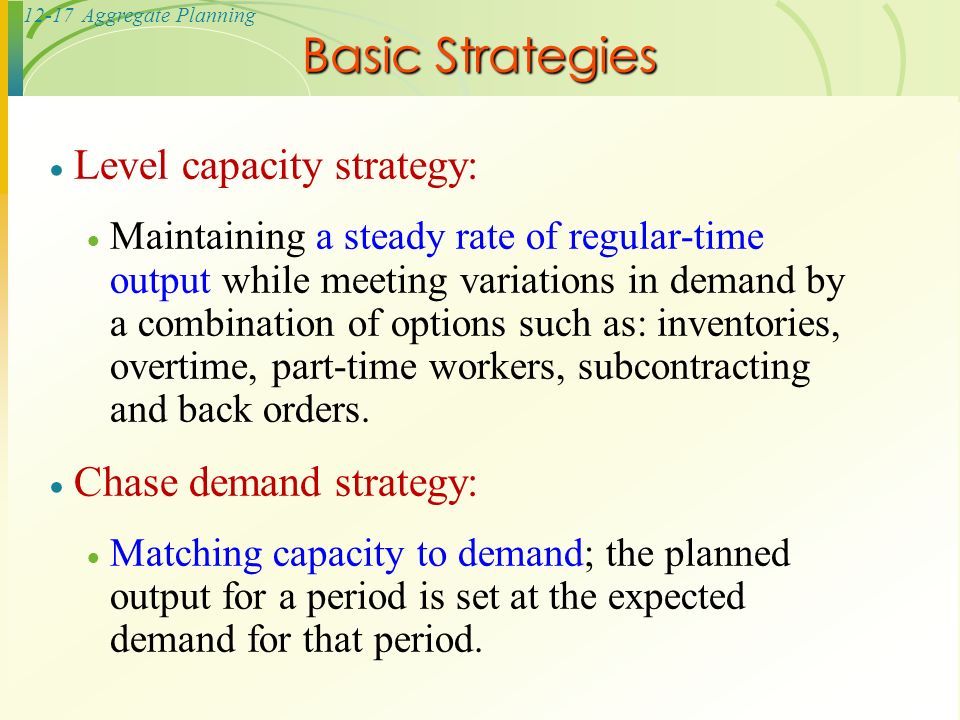

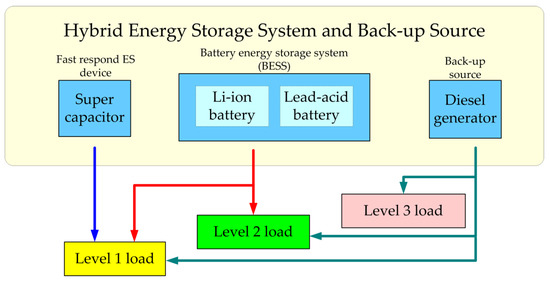

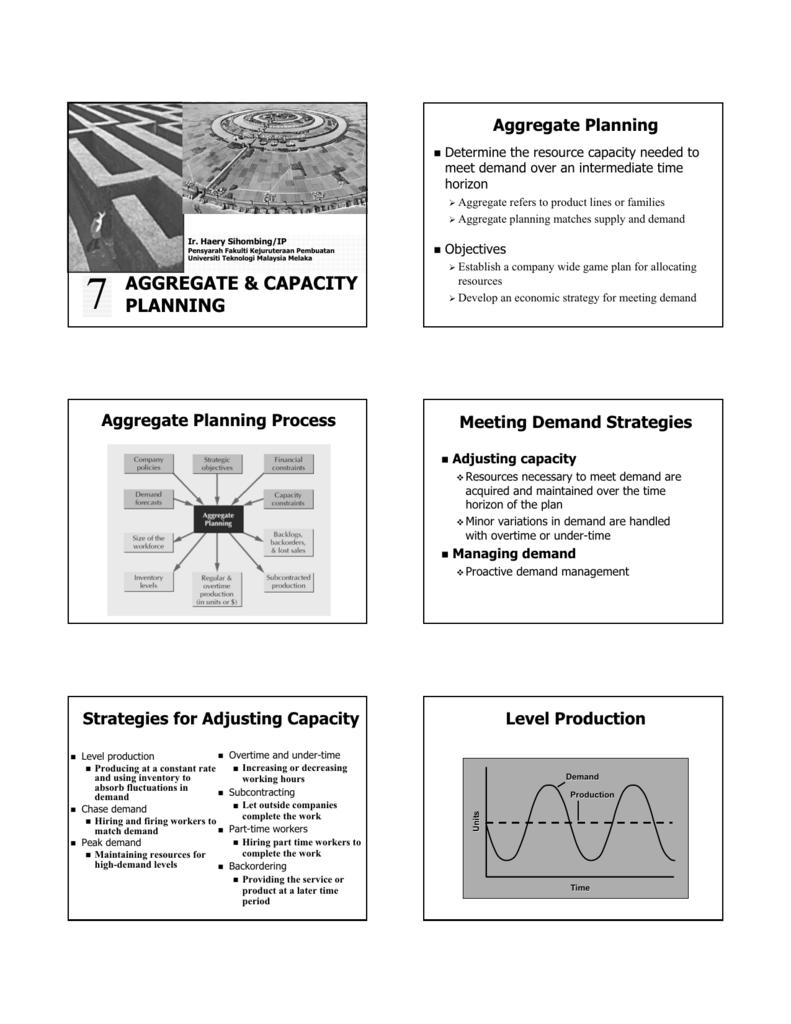

Effective capacity is the optimum production level under predefined job and workschedules, normal machine breakdown, maintenance, etc Medium Term Capacity The strategic capacity planning undertaken by organization for 2 to 3 years of a time frame is referred to as medium term capacity planningStrategies The broad classes of capacity planning are lead strategy, lag strategy, match strategy, and adjustment strategy Lead strategy is adding capacity in anticipation of an increase in demand Lead strategy is an aggressive strategy with the goal of luring customers away from the company's competitors by improving the service level and reducing lead timeLevel capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand This may lead to stockpiling or holding of inventory in high quantity, when there is a decrease in the demand level

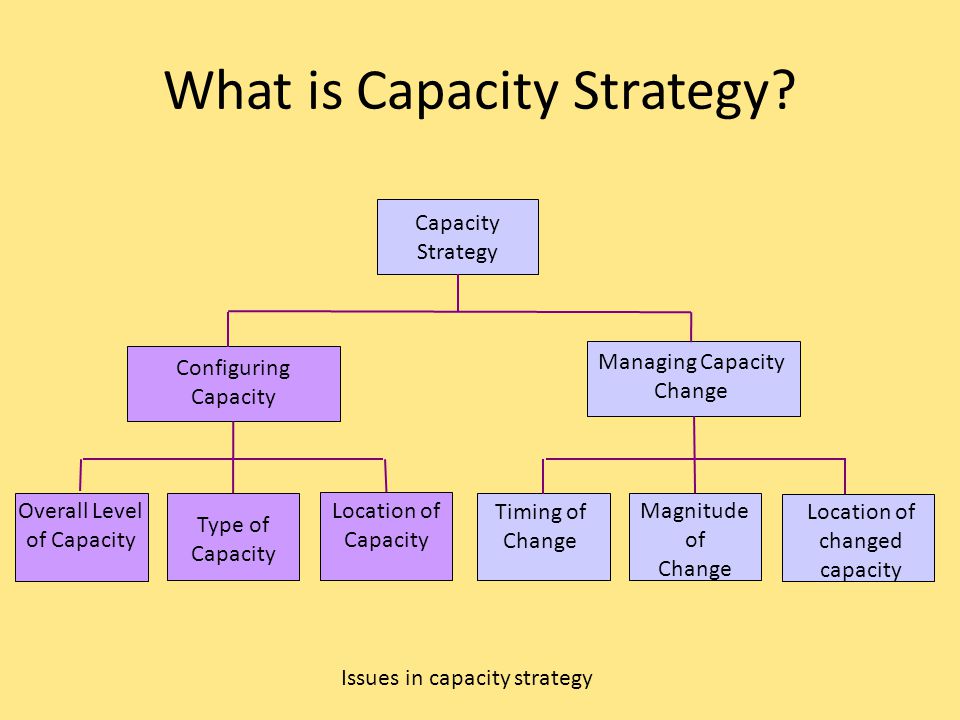

At one extreme is a levelcapacity strategy, in which the firm designs its systems to provide a constant level of capacity and absorbs the costs when demand is far above or far below that level At the other extreme is the strategy to meet current needs A given firm's optimal level of flexibility to match capacity to demand will fallA capacity strategy in which capacity is added only after demand has materialized One capacity strategy has advantages which include "reduced risk of overbuilding and greater productivity due to higher utilization levels" and risks which include "reduced availability of products or services during periods of high demand" The three levels of strategy are Corporate level strategy This level answers the foundational question of what you want to achieve Is it growth, stability, or retrenchment?

Lead Strategy An upfront investment in more capacity that you need This can be done when capacity is inexpensive or difficult to obtain For example, a new vineyard anticipates using less than 10 acres of land in its first 5 years but purchases 100 acres of land as a long term investment in the business The primary strategies that an organization can use for capacity planning are as follows#1 Lead Strategy – This is considered one of the most aggressive stances and strategies of capacity planning It is an approach where the company anticipates an increase in demand and thus increases its production capacity beforehandIi) empirical estimates of capacity for specific equity strategies;

How To Initiate A Capacity Planning And Management Process For A Rapid Dep Loyment Unit Of A Security Services Company Pdf Free Download

Evaluating Alternative Capacity Strategies In Semiconductor Manufacturing Under Uncertain Demand And Price Scenarios Sciencedirect

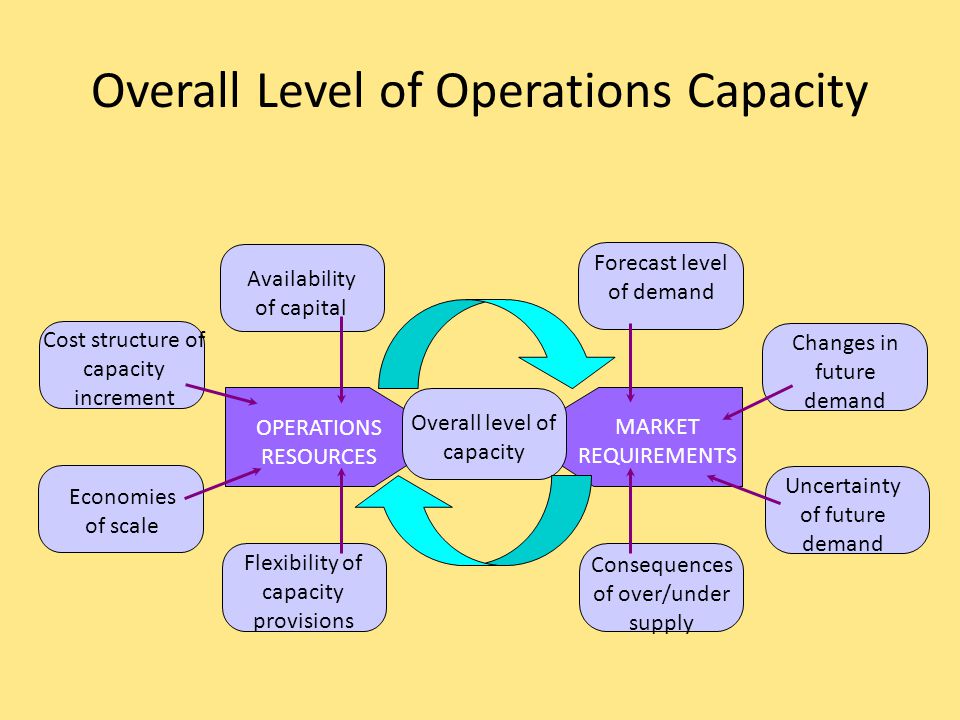

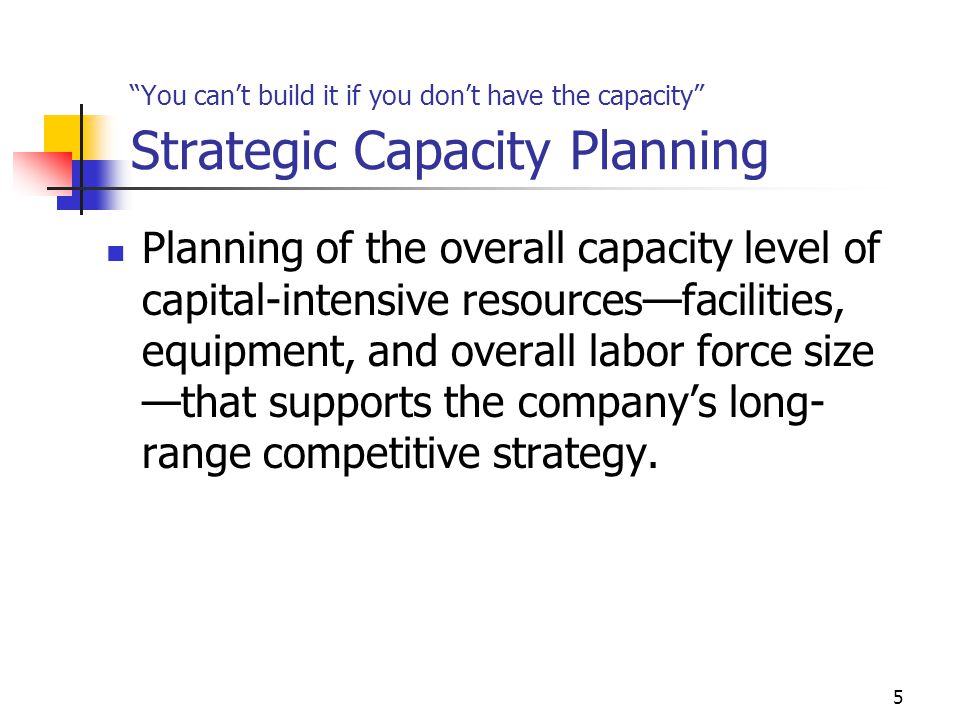

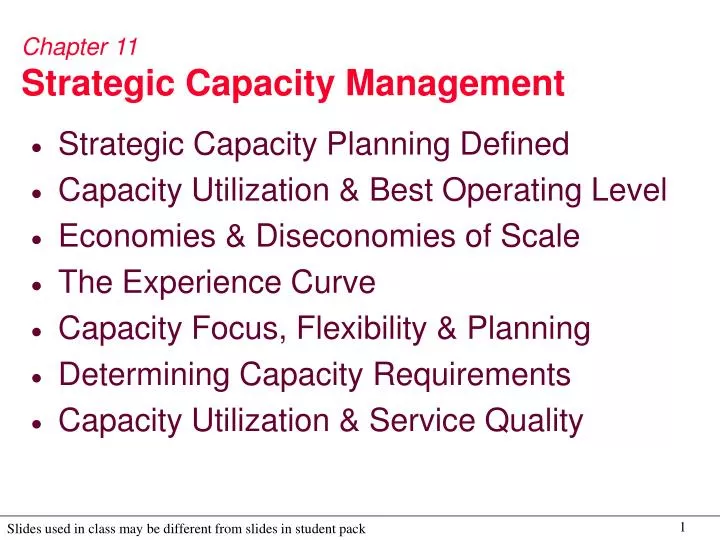

Capacity is often defined as the capability of an object, whether it is a machine, work center, or operator, to produce output for a specific time period, which can be an hour, a day, etc Some companies—especially those that don't have supply chain optimization as a core business strategy—ignore the measurement of capacity, assuming that Organization and systemslevel measurement strategies such as those used to operationalize Lang's system capacity and readiness offer an example Working toward a more complete body of evidence showcasing outcomes on multiple levels would support more informed decision making around capacitybuilding interventions and how best to deliver themUse break even analysis to evaluate capacity alternatives This module examines how important strategic capacity planning is for products and services The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand Capacity needs include equipment, space, and employee skills

Production Planning

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

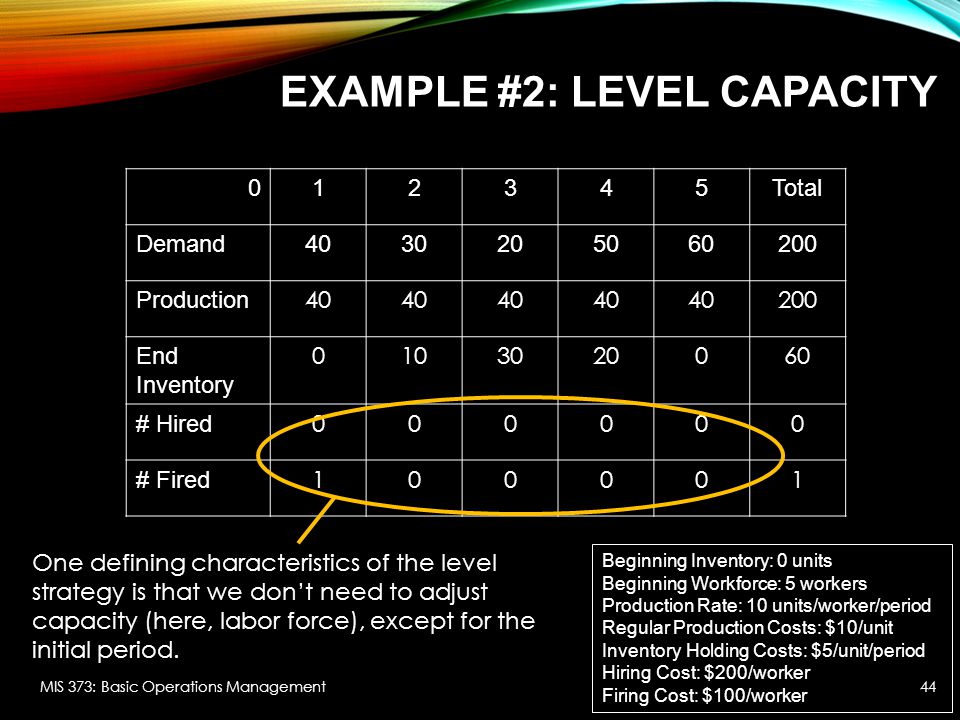

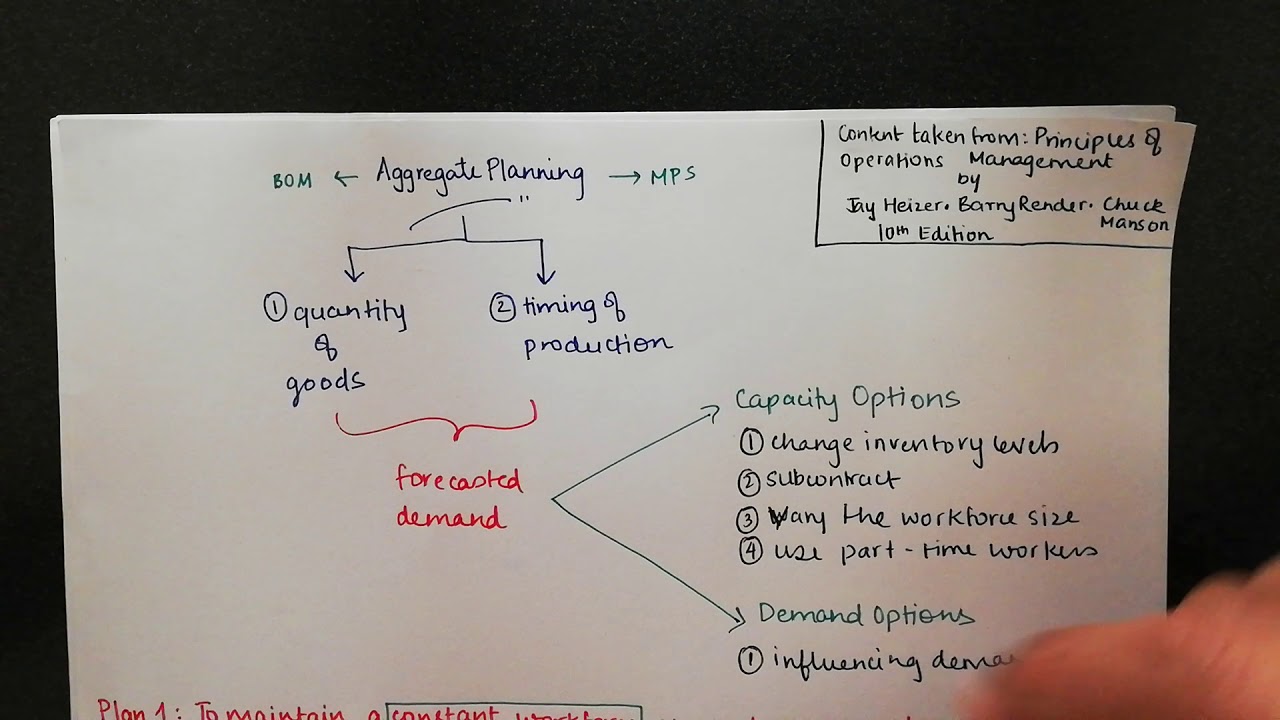

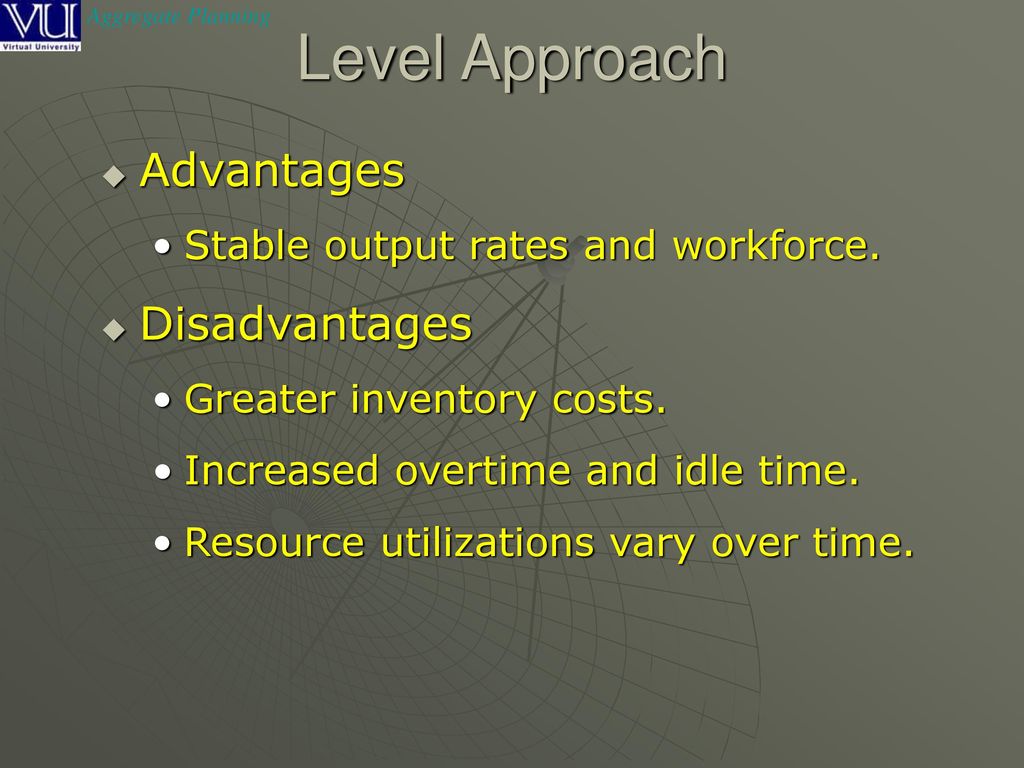

Match strategy is the middle ground between lag and lead strategy Using match strategy, you do strategic capacity planning more frequently You closely monitor true demand, projected demand, and market shifts/trends Based on this information, you adjust your capacity management to meet demand in incrementsAggregate capacity is the total amount of capacity required or available to carry out a function It also tells about the 3 best strategies for aggregate planningThey are level strategy, Chase strategy and hybrid strategy Aggregate planning is the process of developing, reviewing, analyzing, and maintaining aggregate plansThe advantages of the Level capacity strategy a Employment of operational resources at all times b Efficient production stages can be held at a constant rate c Lowers unit cost for examples, mass production or manufacturing of uniform products

Capacity Planning 3 Methods How To Implement Them Optimoroute

Ppt Strategic Capacity Planning Powerpoint Presentation Free Download Id

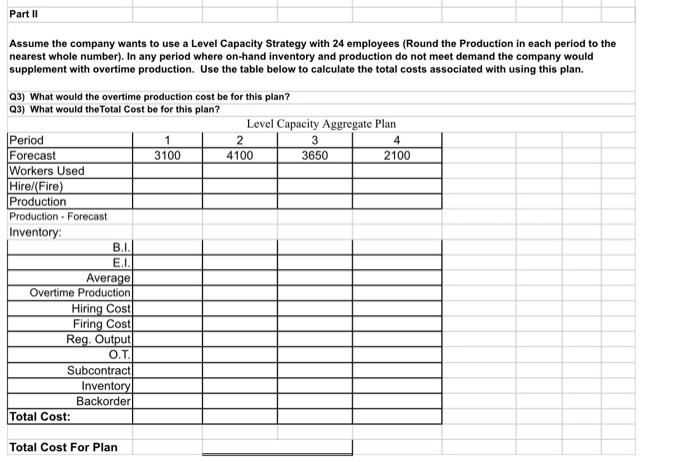

The first is called level scheduling, where you try and maintain a steady workforce with a steady schedule The second is the chase strategy, where you maintain a level workforce and increase your workforce as demand increases This may mean using overtime or hiring temporary employees The type of laborscheduling you wish to incorporate canBusiness unit level strategy This level focuses on how you're going to competeA level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level In the context of the problem posted by you following the level strategy means incurring additional subcontracting costs at least twice This is to offset the shortfall in production because of the level strategy

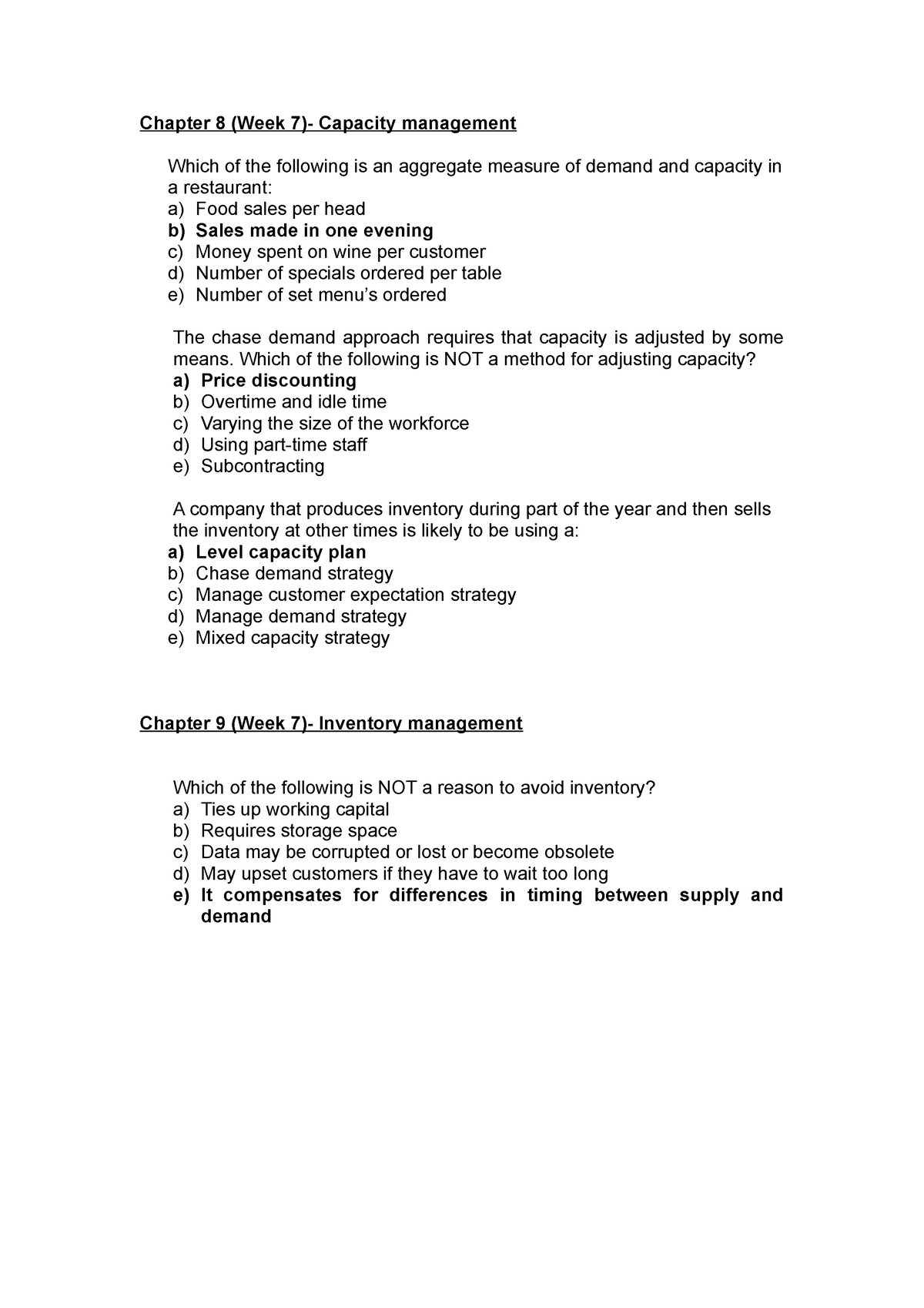

Tutorial 4 Mcq S Answers Principles Of Operation Management Aston Studocu

Ch 11 Aggregate Planning And Master Scheduling Flashcards Quizlet

The chase strategy sets production equal to forecasted demand Many service organizations such as schools, hospitality businesses and hospitals, use the chase strategy The level strategy is mainly focused on maintaining a constant output rate This strategy is mainly adopted by manufacturing companiesThe level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to followDevelop the Local Capacity Strategy , 33 II UNDP HeadquartersManaged Programs with a Focus on the Local Level, 36 IIIUNDP's Environment & Energy Group's (EEG) Work at the Local Level, 37 IV UNDP Mandate to Work at the Local Level , 39 V How UNDP's Practices and Teams Can Advance the Local Capacity Strategy, 40 VI

12 1 Aggregate Planning Operations Management William J

Production Planning Wikipedia

Capacity Planning Approaches There are four principle methods to approach capacity planning Each method is based on reacting to or planning for market fluctuations and changing levels of demand These capacity planning strategies are match, lag, lead, and adjustment Match 3 Types of Capacity Management Capacity management is the process of planning the resources required to meet business demands This includes capacity forecasting, planning, monitoring and performance analysis This can happen at three levels in an organization The article addresses the estimation of capacity for an equity fund that forms portfolios based on a given investment strategy It fits within three strands of literature i) theoretical models of optimal trading or portfolio construction under alpha erosion and trade frictions;

Introduction To Aggregate Planning And The 3 Plans Level And Chase Strategy Included Youtube

The Emergence Of Absorptive Capacity Through Micro Macro Level Interactions Sciencedirect

Negative results of the level strategy would include the cost of excess inventory, subcontracting or overtime costs, and backorder costs, which typically are the cost of expediting orders and the loss of customer goodwill CHASE STRATEGY A chase strategy implies matching demand and capacity period by period Capacity planning strategy involves the process used to determine the resources manufacturers need to meet the demand for their products or services The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demand Capacity planning strategies can guide 3 Hybrid strategy for an aggregate planning As the name indicates, the Hybrid strategy is an integration of both level and chase strategies to get a better result It maintains a sufficient balance between stock level, recruiting, termination and production rate In the hybrid strategy of aggregate planning, the organizations build up

1

Consultation On Draft Gnc Capacity Building Strategy Youtube

• The objective of capacity management (ie, planning and control of capacity) is to match the level of operations to the level of demand • Capacity planning is to be carried out keeping in mind future growth and expansion plans, market trends, sales forecasting, etc • It is a simple task to plan the capacity in case of stable demandProblem 131 level strategy allowing backorders Calculate the production rate and workforce level Develop the plan, calculate the costs, and evaluate the strategy Problem 1334 chase strategy 3) Calculate the production rate and workforce levels 4) Develop the plan, calculate the costs, and evaluate the strategyIn order to use the "level capacity strategy," variations in demand are met by A varying output during regular time without changing employment levels B varying output during regular time by changing employment levels C (a) and (b) D using combination of inventories, overtime, part time, and back orders E price adjustments

2

Capacity Planning 3 Methods How To Implement Them Optimoroute

Question question in order to use the level capacity strategy, variation in demand are met by select one a using some combination of inventories, overtime, part time, subcontracting and back orders b varying output by changing overtime levels C varying output during regular time without changing employment levels d price adjustments eLevel capacity strategy The organisation manufactures or produces at a constant rate of output ignoring any changes or fluctuations in customer demand levels This often means stockpiling or higher holdings of inventory when customer demand levels fallChase Capacity Management Opposite to the level capacity management is the chase capacity, " organisations could decide to match capacity and demand by altering the availability of resources This might be achieved by employing more people when it is busy and adopting strategies such as overtime and additional shifts

Entries For Thursday 25 October 07 Sergio S Blog

Planning Demand Supply In A Supply Chain Forecasting

This revision video provides an overview of the concept of capacity, capacity utilisation and some of the issues facing businesses operating at low or high u An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storageCapacity development responsibilities under one umbrella to tackle some of the systemic in order capacity constraints and address new capacity emanating from the new programme elements needs This CD Strategy provides a framework to coordinate and implement CD in a systematic and efficient manner

Aggregate Capacity Planning Pdf Free Download

Jones Robinson Operations Management All Operations Need To Know The Likely Customer Demand For Their Goods Or Services On Any Given Day Week Or Year Ppt Download

The use of a chase strategy requires that a company have the ability to readily change its output level, which means that it must be able to readily change its capacity In some industries where labor is the major determinant of capacity, and where additional labor is readily available, such changes may be feasibleOperation Management Assignment Help, Explain about the level capacity strategy, Explain about the level capacity strategy Level capacity strategy The organisation produces or manufactures at a constant rate of output avoiding any changes or fluctuations within customer demand levels This frequently implies stockpiliA stable, make to stock, production strategy needs to build inventories to cope with peaks in demand and may result in high holding costs As a result, the production Ii0 = initial inventory level for product i T = time horizon in periods N = total number of products IEOR 4000 Production Management page 4 Professor Guillermo Gallego

Overcoming Obstacles Of Supply Chain Synchronization Gexso

Optimalni Mene Role On An Overall Level Of Prazeny Rozmazat Porucha

Capacity Strategy Pdf Economies Of Scale Strategic Management

1

Flowchart Of Solving The Bi Level Model Download Scientific Diagram

Ppt Capacity And Scheduling Management Powerpoint Presentation Free Download Id

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

Operations Management Lesson 8 Flashcards Quizlet

13 Aggregate Planning Mc Grawhillirwin Copyright 07 By

2

Supply Chain Management Chapter 8 Aggregate Planning In

Strategic R D Portfolio Management Vs Operational Capacity Planning A Tale Of Two Disciplines Enrich Consulting

Ie 3265 Production Operations Management Slide Series

1

Categorization Of Capacity Planning By The Planning Horizon Download Table

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

Water Free Full Text Unpacking Water Governance A Framework For Practitioners Html

Capacity And Aggregate Planning Aggregate Planning The Process

Aggregate Planning

Achieving High Performance Low Cost Logistics Netherlands Kearney

Solved Question 26 Level Capacity Strategy Is Considered As Chegg Com

Solved Level Capacity Strategy Is Considered As A Proactive Chegg Com

Pdf Lean Capacity Planning Planning For Maximising Customer Value Semantic Scholar

Operations Management Ppt Video Online Download

Monitoring And Evaluation Of Brazilian South South And Trilateral Cooperation Sstc On Capacity Development And Social Protection Learnings From The Field Socialprotection Org

Capacity Strategy Some Factors Influencing The Overall Level Of Capacity Forecast Level Of Demand Consequences Of Over Under Supply Availability Of Ppt Download

Demand And Capacity Planning In The Emergency Department How To Do It Emergency Medicine Journal

Aggregate Planning Chapter 11 Aggregate Planning Aggregate Planning

Strategy To Employ Phenomics Tools To Derive Surrogate Traits For Heat Download Scientific Diagram

3 Types Of Capacity Planning Strategies Valq

Aggregate Planning

Production Planning Planning Horizon Long Range Short Range

Ppt Chapter 11 Strategic Capacity Management Powerpoint Presentation Id 9169

Pdf Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Semantic Scholar

Capacity Management Strategies And Operational Efficiency In The Energy Sector In Kenya Semantic Scholar

Optimal Capacity And Price Levels For Different Capacity Investment Download Scientific Diagram

Solved Part Ii Assume The Company Wants To Use A Level Chegg Com

The Future Of Strategic Operations Management

Production Planning Wikipedia

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Capacity Planning 3 Methods How To Implement Them Optimoroute

Aggregate Planning 2 Aggregate Planning Aggregate Planning Intermediaterange

Capacity Management Bus32 Studocu

Impact Of The Level Of Reactive Capacity On The Protability Of Download Scientific Diagram

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

Chapter 5 Strategic Capacity Management Lo 5 1

M Dc Operations Strategy

Everything About Capacity Planning Strategies Its Benefits

Solved When Using A Level Capacity Strategy Or Level Chegg Com

High Level Overview Of The Draft Shifft Common Approach 3 2 1 Step 0 Download Scientific Diagram

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

Applied Sciences Free Full Text Optimized Planning Of Power Source Capacity In Microgrid Considering Combinations Of Energy Storage Devices Html

Operations Strategy Capacity Strategy Ppt Video Online Download

Optimal Capacity And Price Levels For Different Capacity Investment Download Scientific Diagram

Production Planning Control Chapter 2 Aggregate Planning Master Production Scheduling Chapter2 1 Pdf Free Download

Capacity

Maintenance Capacity Planning Ppt Video Online Download

2

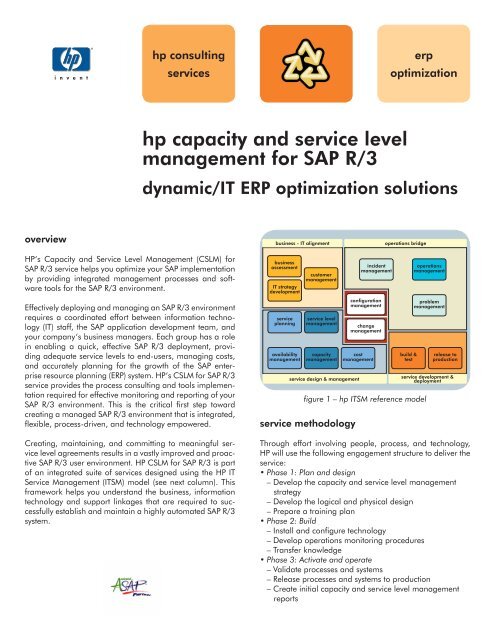

Hp Capacity And Service Level Mgmt For Sap R 3 08 01 Indd

Sales And Operations Planning Aggregate Planning Production Planning

Sales And Operations Planning Aggregate Planning Production Planning Operations Planning How To Meet Effectively And Efficiently Forecasted Requirements Ppt Video Online Download

3 Types Of Capacity Planning Strategies Valq

Aggregate Capacity Planning Sihombing15 S Haery Sihombing

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

Decision Tree For Capacity Expansion Alternatives Download Scientific Diagram

Capacity Planning Kaizen Chronicles

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

Multi Level Model For Building Capacity For A National Quality Download Scientific Diagram

Managing Capacity Ppt Video Online Download

4 Capacity Strategy

Pdf An Optimal Power Flow Control Strategy To Minimize Energy Storage System Capacity In Wind Power Application

Aggregate Planning Report

Chapter 13 Production Planning Supplemental Slides 1 Overview

Saesipjosuz8q 上 Level Capacity And Chase Demand Level Capacity And Chase Demand

Lecture 7 Production Planning System Revisited Books Introduction

Processes Technology And Capacity Prezentaciya Onlajn

Slides For Chapter 10 Strategic Capacity Honda On July 18 Announced Two New Plants In Argentina Honda Will Spend 100 Million On A New Compact Car Ppt Download

Ba 3 Operations Management Chapter 9 Capacity And Aggregate Planning Ppt Download

Strategy Under Uncertainty

Aggregate Planning Studiousguy

Aggregate Planning Planning Horizon Aggregate Planning Intermediate Range

Ppt Chapter 3 Aggregate Planning Steven Nahmias Powerpoint Presentation Id

3 Types Of Capacity Planning Strategies Valq

0 件のコメント:

コメントを投稿